Is Conformal Cooling Right for You?

Conformal cooling is a working solution with proven benefits for injection molding. In addition to increasing profits by up to 55 percent, customers have reported the following benefits of using conformal cooling:

Improved Cycle Time

- Reduced injection molding cycle time by up to 70%

Better Part Quality

- Reduced warpage

- Reduced scrapped parts

- Reduced surface roughness from 100 to 20 microns

Lower Total Cost of Ownership

- Reduced design time by up to 75%

- Reduced mold production cost by an average of 16%

- Reduced production work hours by up to 50%

- Reduced temperature across the mold by up to 86%

What Part of the Mold Should be Cooled Conformally?

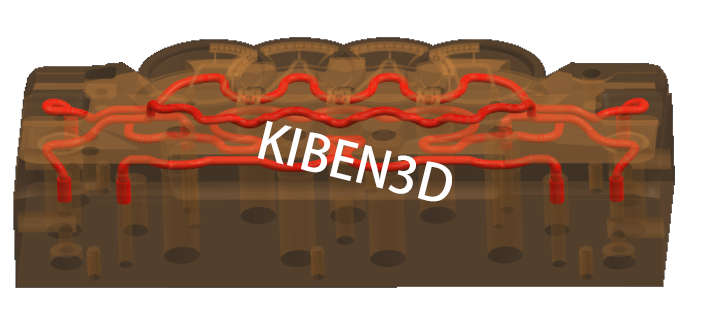

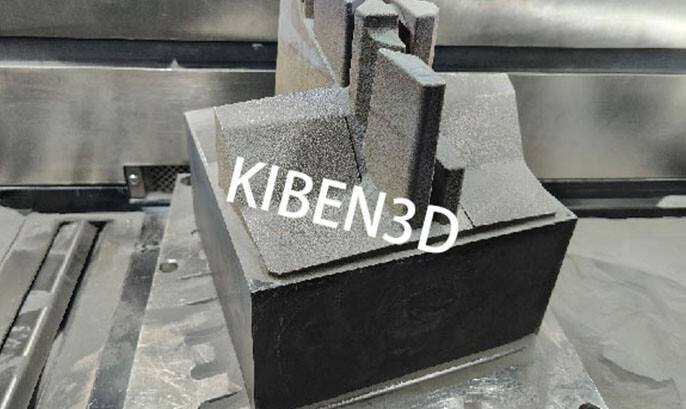

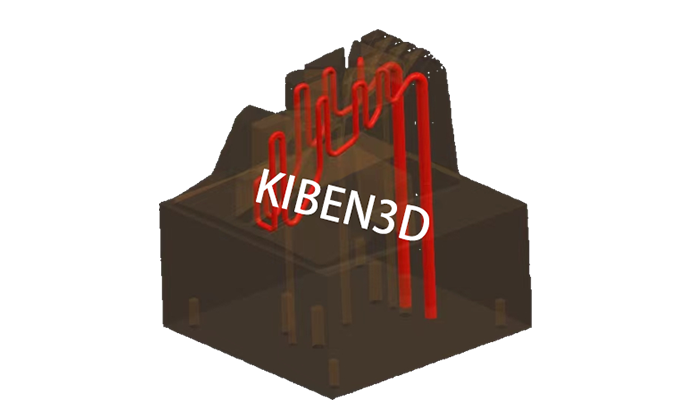

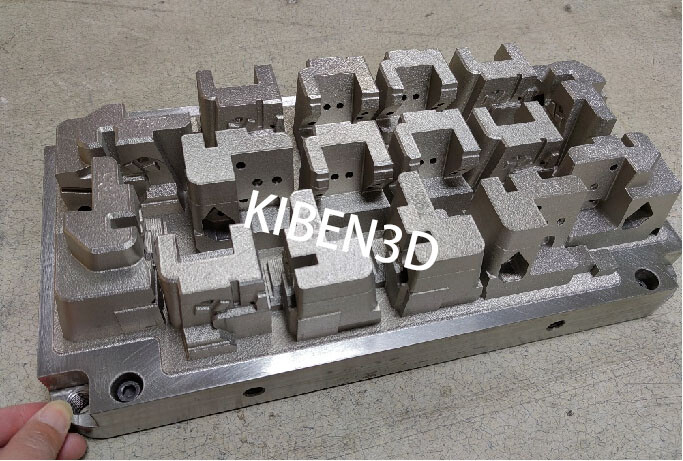

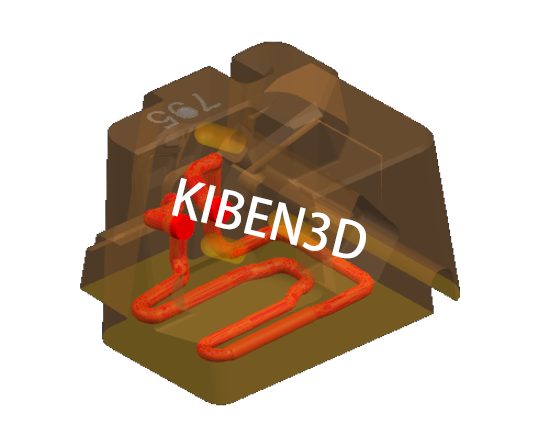

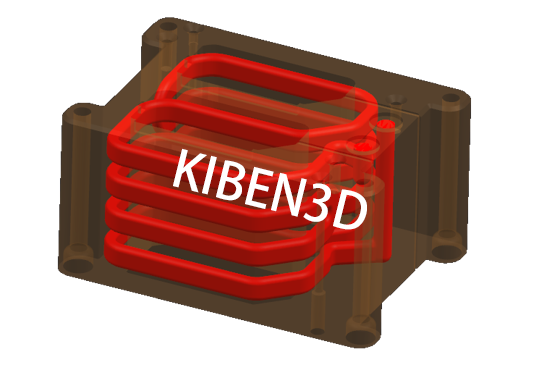

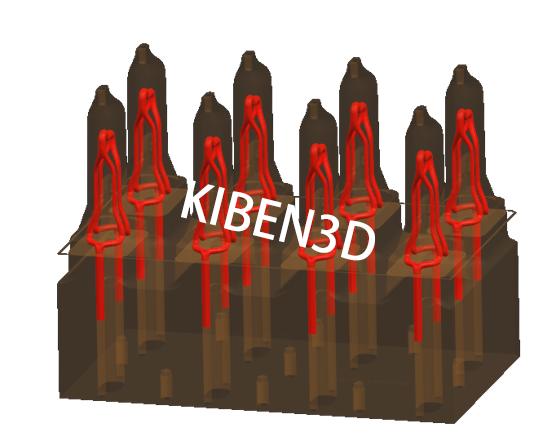

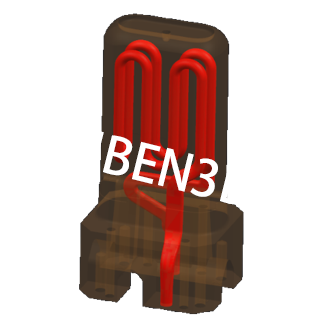

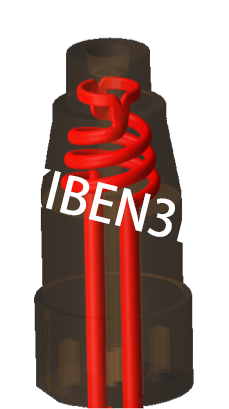

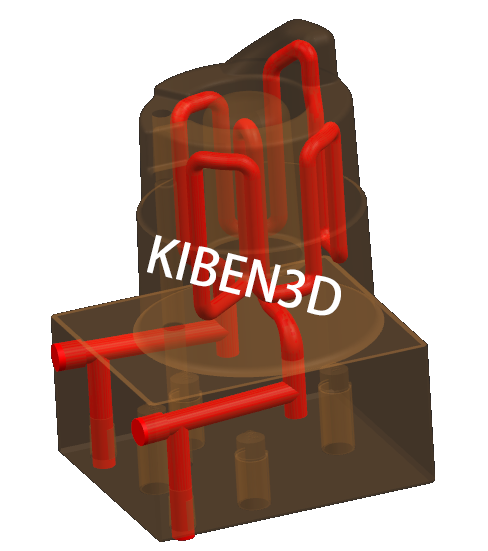

Conformal cooling can benefit all types of molded parts, especially complex parts. However, you do not necessarily need to 3D print your entire mold—the key is to detect the areas that would benefit from conformal cooling and use AM only for those areas.

The primary issue with traditional cooling methods is that they can't reach the places where cooling channels are needed. Conformal cooling has the most significant effect on injection molds that are experiencing problems with warpage during production because of irregularities or imbalances in the cooling process.

Producing conformally-cooled inserts to address key problem areas in the mold is, with the right tools, straightforward and very effective.

See lf lt's Right for You

Watch an on-demand webinar to learn more about conformal coolino

including how it compares to traditional cooling processes and how

it's accomplished.

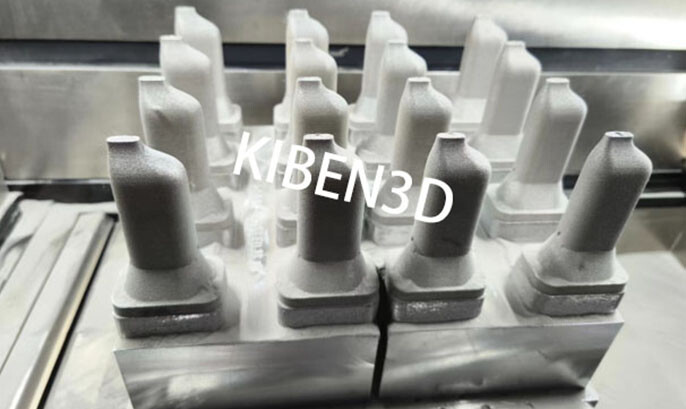

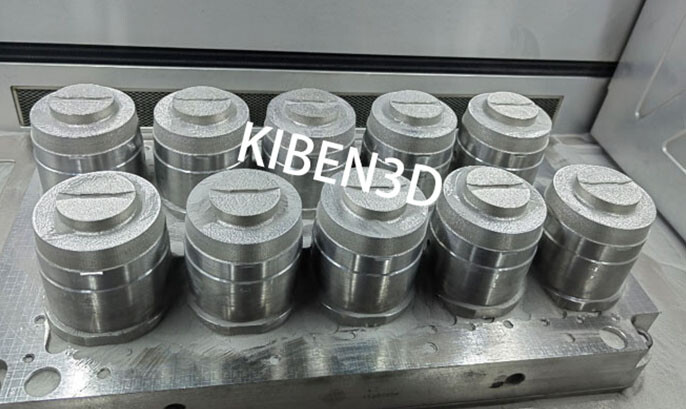

Conformal Cooling Case Study